Testing

Get in touch

Call us now on

08456 528 528

Email your enquiry to sales@linkstudpsr.com

A full list of contacts can be found on the contact page

LinkStud PSR has in-house testing facilities, ensuring full quality control during production

The shear studs used in our Punching Shear Reinforcement system are manufactured in-house using a 500C Grade deformed reinforcement bar, commonly known as rebar. Our studs conform to the strength and dimensional requirements incorporated withing EC2 and BS8110.

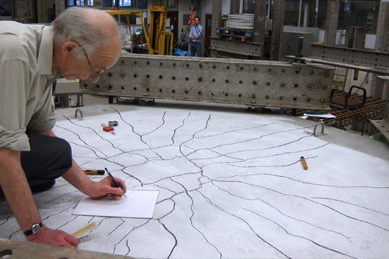

CARES Technical Approval Testing of the LinkStud PSR™ System was carried out at Cambridge University under the supervision of Prof. Dr. Paul Regan BSc Ph.D. CEng FIStructE - a global authority on shear, punching and flat slabs.

Professor Regan has been involved in research and the development of code provisions on flat slabs, punching and shear reinforcement for slabs for over 40 years and has been a member of various committees of the IStructE, ACI, IABSE, and RILEM.

He has published more than 60 papers on structural concrete, many of them concerned with shear, punching and flat slabs.

|

|

|

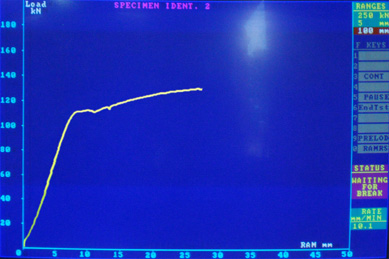

Destructive testing of our shear reinforcement studs is performed in-house

CARES Technical Approval Testing at Cambridge University

|

|

|

We have on-site access to a 500Kn Mayes 4 Column Vertical Universal Tensile Testing Machine.

This enables us to complete tests in house, saving valuable time in the manufacturing process and reduce lead times.

Shear studs are tested to destruction on this machine. Using specially designed jigs and fixtures to ensure the tests are completed accurately and within guidelines.